Writer Biography:

Hello, I’m Jonathon from Rochester, Michigan. I am currently a Plant Biology major, and am planning on switching to biosystems engineering soon. I was very interested in this study abroad because I have been very interested in the way other countries utilize their natural resources and how those strategies can be applied in the U.S. After graduation I plan on working with renewable energies, more specifically algal biofuels.

Pre-Departure:

In the morning of May 15th, we will begin by traveling to the Energy Technology Centre(ETC) in Piteå, Sweden. Piteå is located 100 km south of the Arctic in the Norbotten region of Sweden[1]. The industrial focus of Piteå is energy and sustainable development. Apart from its industrial focus, Piteå is also home to a strong nature-driven tourism industry[2].

Figure 1. Map of Sweden with Piteå highlighted [3].

At the ETC, we will be listening to a lecture by Olov Öhrman about the research being done at the centre and Smurfit Kappa. After the lecture we will be taken on a guided tour of the facility. Later in the day we will take another guided tour, this time of Smurfit Kappa, by Peder Fahlman. Smurfit Kapa is a leading producer of paper-based packaging in the world. Smurfit Kappa employs over 41,000 people and has production sites in 32 countries[4].

May 15th

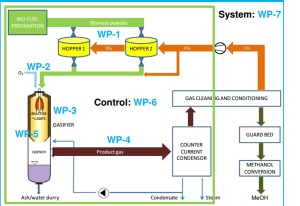

In the morning we traveled about 45 minutes south of Luleå to Piteå, Sweden. At our first stop in Piteå, we visited the ETC. At ETC we attended a presentation by Olov Öhrman of the ongoing projects that the nonprofit is working on. The main focus of the presentation was biomass and the Pressurized Entrained flow Biomass Gasification (PEBG). During this process, biomass is heated to temperatures exceeding 1000 ˚C at high pressure and low oxygen levels[6]. As a result of the low oxygen heating, syngas (H2+CO) is produced, which can be used directly as an energy source, or converted to methanol to be more energy dense. At this time, ETC is currently working on optimizing their process for the gasification of black liquor with hopes of using it for lower quality biomass like bark and other tree matter.

.

Figure 2. Diagram of PEBG process [6]

After visiting the ETC building, the group had lunch and proceeded to start a tour of the Smurfit Kappa paper mill, led by Pedar Fahlman. The paper plant, which produces large sheet paper for the outside of cardboard boxes, is the largest of its kind in Europe. The tour led us through many of the machine-filled and awe inspiring portions of the facility. Unlike many other paper mills, this plant uses sustainable fuels and cogeneration to aid in supplying its energy needs[7]. The mill can currently produce about half of the energy needed to produce its paper, drastically lowering the amount of energy they need to purchase. With waste heat from the plant’s energy production, the mill is able to dry wood chips to aid in efficiency, heat liquor for chemical recovery, heat water for fiber washing, and provide district heating for the town of Piteå [7]. By providing heat for the town, the mill is able to increase its overall profit.

Figure 3. Overview of Smurfit Kappa facility

Figure 4. Pedar Fahlman explaining byproducts of the paper-making processes

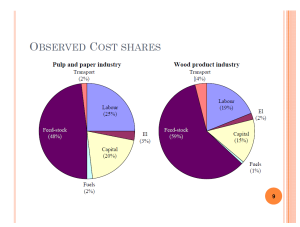

After the tour in the Smurfit Kappa mill, we traveled back to LTU for a presentation on the economics of woody biomass by Robert Lundmark. Sweden has over 4 billion hectares of forest land, with the production of woody biomass increasing at an average of 3% per year. The growth of biomass exceeds the rate of harvesting, allowing for an increase of biomass production without an adverse effect on the environment. The biomass throughout Sweden consists mainly of private owners (50%), public companies (14%), and private companies (26%) [5]. To complement the large volume of biomass available in Sweden, the country utilizes policy to persuade companies to spend resources on improving technology.

Figure 5. Pie graphs of the costs attributed to the paper and woody biomass industry [5].

Figure 6. piles of wood chips outside of the Smurfit Kappa paper mill.

Figure 7. Lumber waiting to be processed at the Smurfit Kappa paper mill.

Figure 8. Final product of Smurfit Kappa paper mill.

Bibliography:

1) Tourism and Events. (n.d.). . Retrieved May 13, 2014, from http://www.pitea.se/en/tourism-and-event/

2) Town of Pitea. (n.d.). . Retrieved May 13, 2014, from http://www.pitea.se/en/Town-of-Pitea/

3) Pitea in Sweden. (n.d.). . Retrieved May 13, 2014, from http://upload.wikimedia.org/wikipedia/commons/1/1c/Pite%C3%A5_in_Sweden.png

4) About us. (n.d.). Smurfit Kappa . Retrieved May 13, 2014, from http://www.smurfitkappa.com/vHome/com/Pages/Default.aspx

5) Lundmark, Robert. “The Economics of Woody Biomass”. Luleå Technical University, Luleå, Sweden. Personal Interview. 15 May, 2014.

6) Öhrman, Olov. Energy Technology Center, Piteå , Sweden. Personal Interview. 15 May, 2014.

7) Fahlman, Pedar. Smurfit Kappa Kraftliner, Pitea, Sweden. Personal Interview. 15 May, 2014.

![Map of Piteå, Sweden [3]](https://deandse2014.files.wordpress.com/2014/04/pitec3a5_in_sweden.png?w=111&h=243)

We’ve heard many, if not all, of the speakers so far from Sweden tell us the large quantities of Biomass that Sweden has to offer, but if that is what is driving policy changes toward renewable energies, what is stopping the US? The Biomass Resource Assessment of 2012 outlined great potentials for biomass throughout much of the US. (1) So what would you consider to be the main reason that is stopping the US from adopting all the policies that Sweden has? There are many different ideas, but what do you think is the largest contributing factor to why the US is not trying harder to implement policy changes to utilize the domestic biomass we already possess.

1) http://www.ucsusa.org/clean_vehicles/smart-transportation-solutions/cleaner_fuels/ethanol-and-other-biofuels/biomass-energy-resources.html

I believe the main thing stopping the US from adopting policies like they have in the Sweden has a lot to do with lobbying from large corporations, infrastructure costs to change power plants, and sheer population size. according to the EIA, we produced about 120 million MWh (1 billion 120W lightbulbs) of renewable energy in January of 2014 alone. Although that may seem like a very large number that might only be 9% of our total monthly energy consumption.

http://www.eia.gov/electricity/data/browser/#/topic/0?agg=2,0,1&fuel=vvg&geo=g&sec=g&linechart=ELEC.GEN.NUC-US-99.M~ELEC.GEN.HYC-US-99.M~ELEC.GEN.AOR-US-99.M~ELEC.GEN.HPS-US-99.M~ELEC.GEN.OTH-US-99.M&columnchart=ELEC.GEN.ALL-US-99.M&map=ELEC.GEN.ALL-US-99.M&freq=M&start=200101&end=201402&ctype=linechart<ype=pin&rtype=s&pin=&rse=0&maptype=0

Do you think that if residential estates of the US started adopting their own sources of electricity, (i.e. small biogas production facilities for farmlands, or even solar panels on the rooftops of buildings), and decided to sell their production to the grid, would the lobbying in the US encourage such behavior; or do you think that the large corporations using fossil fuels would fight to get such behaviors outlawed.

The main reason I ask is throughout our drives through Germany we have seen many many solar panel farms as well as paneling atop rooftops and I just feel that if the US was going to try and adopt this kind of behavior the large corporations would attempt to get government backing for outlawing any private production of electricity.